Aeronaut automated cutters are being used around the world to cut inflatable products in industries from marine hulls to bouncy castles and display products.

Additionally, Aeronaut's Hypergrinder attachment is used to sand, grind or buff the edges of hypalon to allow perfect bonding a huge time saver.

Many of our customers have commented that the ability of a cutter to draw or plot is actually more important than the cutting itself. So much more detail can be plotted automatically than can be drawn by hand that the end result of computer aided plotting and cutting is a far more accurate and consistent product.

Marine hulls are typically made from PVC or Hypalon with some very heavyweight materials being used for the bottoms and rubbing strips on boats. Most inflatables such as bouncy castles are made with much lighter PVC fabric. Neither presents a cutting problem on Aeronaut automated cutters due to the high tool forces available.

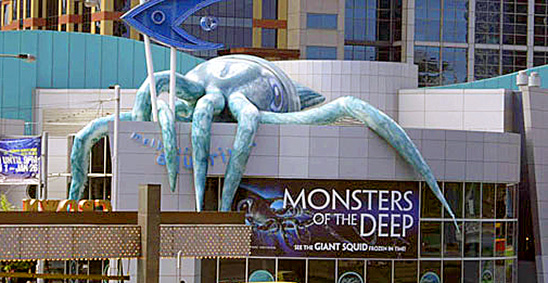

Lightweight inflatables for indoor and outdoor display purposes can be made from materials like Nylon and polyester which can be very effectively cut on a laser cutter.

All Elektron machines, even the Elektron Mono LC, can be fitted with optional high pressure steered tool axes for either cutting heavy materials or for drill punching. The pressure on the tool can then by varied by almost double the force available on a standard machine.

Both rotary blade and drag blades are used to cut fabrics used for inflatables. The majority of cutting is done with a 28mm rotary blade, and small rotary blades or drag blades are used where greater detail is required, for example on valve cutouts and other fittings. Drill punches can be used to cut eyelet holes.On the Elektron Quattro, with up to four tools available, you can fit more than one size of drill punch.

In bouncy castle production, the automated cutter is often used to draw outlines of logos and other designs onto the fabric before assembly for sign-painting after fabrication. The ability of Tangent to handle EPS or Illustrator files makes this easy. Shapes can even be traced, smoothed, vectorised and scaled with Tangent's built-in bitmap trace function.

Since all types of Aeronaut automated cutters are in use on various types of inflatable work, the choice is often made simply on budget.

The Elektron Mono LC is a good choice for working with bouncy castles where a rotary blade and pen can do almost all the work. For the small amount where a different tool is needed, Aeronaut's Cam-lock tools mean you can still fit the tool you need, whenever you need it.

For marine hulls and mixed fabrication, an Elektron Quattro with two, three or four steered tools and Cam-lock quick-change tooling can be a more effective and future-proof investment.

With marine hull and other inflatable products, especially for the factory just starting with automated cutting, one of the main problems is getting existing patterns digitised ready for cutting.

For information about the design and patterning of inflatable products, see thePatterning Inflatable Products menu.