Aeronaut manufactures a range of very wide gantry machines which can be used for large-scale cutting, plotting and processing of materials as diverse as concrete, carpet, stencils and composite panels.

Aeronaut manufactures a range of very wide gantry machines which can be used for large-scale cutting, plotting and processing of materials as diverse as concrete, carpet, stencils and composite panels.

Aeronaut can manufacture cutters and plotters wider than 10 metres (400 inches). In most cases, machines up to 6.5 metres wide (255 inches) use an aluminium gantry and machines wider than that use a fabricated or carbon fibre gantry, depending on the application and loads. Generally, these machines can work as fast as narrow machines and are in many cases working 24 hours a day for 15 years or more.

Machines can be installed either on a platform or vacuum table or even mounted on tracks on the floor depending on the job requirements. Vacuum tables are mostly made to a convenient operating height by Aeronaut while platforms are generally made on-site by local contractors.

And like any Aeronaut machine, ultra-wide cutters can work in all conditions, even in a dusty outback shed.

In boat building, for both recreational and military craft, composite panels are often laid up on large tables, many metres wide. When the material has cured, the panel is then marked out and cut out into bulkheads and frames etc. A wide-span plotter is a very cost-effective way of marking panels accurately and fast before they are cut up, even if the final processing takes place on smaller sized CNC routers.

When patterns are marked by a plotter, it's a simple matter to mark out complex nests of parts and to draw all the details necessary for the down-stream production processes such as hydraulic, electrical and pneumatic services.

Aeronaut has a world wide reputation for tackling special projects whether they be aero-space or building or working with ultrasonic tools or chain saws.

In the production of tilt-slab concrete, where slabs are manufactured in a central factory, a wide-span plotter can be used for marking designs out directly onto the casting table so baffles and fittings can be accurately placed before the concrete is poured. If the marking-out process is done manually, it can take thousands of man-hours per year. This can be reduced to a few hundred by automating the process since a plotter will take 10-12 minutes for a whole table. Of course, there is a great increase in accuracy and reduction of mistakes since the original CAD designs are marked out directly on the table without human interference.

Plotters fitted with either marking pens or sign-blades can be used to mark and/or cut the stencils used to mark out the giant advertising signs in stadiums for televised sporting events. Machines can be either floor mounted or fitted to specially modified cutting tables so the material for the entire stencil can be joined before processing and plotted in sections on the table.

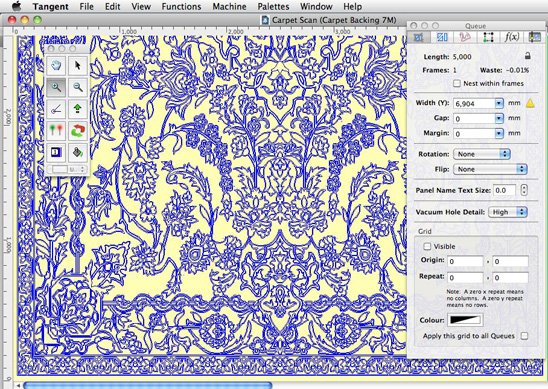

Where bespoke or custom carpets are made, for anything from the Oval office to hotel foyers, the design has to be marked out onto the carpet backing.

Here, Aeronaut plotters, fitted with ink-jet pens, are used to mark the designs on the backing prior to hand-tufting but also Aeronaut has developed special software to automatically trace the original design and to add "paint by numbers" markers to show the operators the colours of wool to use.

Using an automated plotting system instead of a manual one has huge benefits in terms of accuracy, speed and reduced mistakes, even in regions where the labour costs are very low. In most cases, the cost of the Aeronaut component is fairly low because for plotting, simple, low-cost gantries can be used and there is no vacuum table or ancillary equipment to add costs.

Where large amounts of time are spent marking out patterns which are either in CAD format or which can be converted easily to CAD format, the payback time for automating the process is frequently months rather than years.

If you have special requirements for an extra-wide machine, why not contact Aeronaut and find out what we've got to help improve your work?